Bill of Materials (BOM)

The part-book is the ideal bill-of-materials (BOM) Management software solution for automotive suppliers

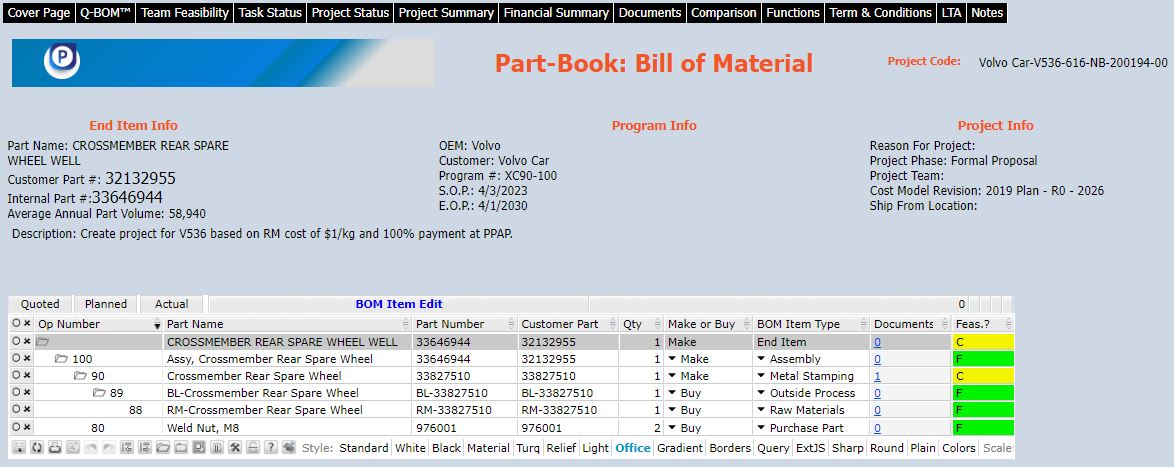

We call the Part-Book a Program, Part and Project Management (3PM) software solution, but the Bill-of-Materials (BOM) is the heart of the system. The BOM is the page that sees the most clicks, because it’s what drives the feasibility, cost and timing of a part; and it’s the central navigation point for entering or reviewing details.

We call the Part-Book a Program, Part and Project Management (3PM) software solution, but the Bill-of-Materials (BOM) is the heart of the system. The BOM is the page that sees the most clicks, because it’s what drives the feasibility, cost and timing of a part; and it’s the central navigation point for entering or reviewing details.

For clarification, here’s our BOM Management related terminology and definitions:

- Bill-of-Materials (BOM) – when we say BOM what we’re referring to is what some other systems may call the Bill-of-Materials and Routing, because it includes the materials that must be purchased to produce the part, plus the value added operations (routing) those materials must go through to be converted into the finished good.

- Bill-of-Materials Item (BOM Item) – each material or operation in the BOM is referred to as a BOM Item and get’s it’s own row in the BOM.

- Bill-of-Materials Item Type (BOM Item Type) – the Part-Book recognizes that their are different types of items in the BOM for most parts. Some common BOM Item Types we see in an automotive part are casting, forging, machining, metal stamping, raw material, plastic injection mold and purchased part, but those are just some examples. Defining the BOM Item Type is important, because it makes it easy to see what goes into making a given part; and because the cost drivers for a casting are different than the cost drivers for a metal stamping or plastic injection molded component.

- Bill-of-Materials Item Attributes (BOM Item Attributes) – the BOM Item attributes are the cost drivers and variables that are associated with determining the feasibility, cost and timing for a given item.

So what is Bill-of-Materials Management and how does the Part-Book do it?

Automotive Suppliers create or receive CAD (Computer Aided Design) files for each part. The CAD file contains the Design Bill-of-Materials (D-BOM) for the part. The D-BOMB includes a list of all the components in the part, including the three dimensional (3D) shape and dimensions, plus the material specifications and tolerances embedded within the file. Over time, the design of most parts evolve, which means an automotive supplier will receive several different files with design variations – some of the files will be study only, and others are “released” as the official design version – a.k.a. an Engineering Change.

The D-BOM defines what needs to be made, but not how to make it. Each company that reviews the D-BOM for a part will come up with their own Manufacturing Bill-of-Materials (M-BOM); in fact, they may have several options they would like to consider. The M-BOM is what some systems refer to as the bill-of-materials and routing; it defines the materials that will need to be purchased to produce the part as well as the value-added operations those materials must be routed through in order to convert them into the finished good. The M-BOM is what gets entered into an automotive suppliers ERP/MRP (Enterprise/Material Resource Planning) system to drive the shop floor.

The D-BOM + Volume + Timing drive the M-BOM. The D-BOM defines what needs to be made, but how many need to be made and when they are needed are important factors. In other words, the most cost effective way to make the widget will vary if you need 300 parts in 3 months -or- if you need 300,000 in 30 months.

So, the Part-Book is a Program, Part and Project Management system that’s driven by a custom engineered Bill-of-Materials (BOM) and Operations, so it governs the data for current production parts, plus it facilitates quoting new business and managing engineering changes. The Part-Book is the system of record for all program, part and project related information, so it seamlessly maintains and controls Design and Manufacturing Bill-of-Materials (BOM) alignment for every part, at every level, including each option or scenario that’s been considered. The Part-Book makes it easy to see the part pedigree that’s been supplied for each program and design revision.

Bill-of-Materials Management is a critical element that is fundamental to an automotive suppliers success – it drives cost and price when quoting new business; and it drives the shop floor once a part goes into production. If you’re tired of chasing data around spreadsheets and want to get everyone on the same page then you need a Bill-of-Materials Management system that will bridge the gap between the D-BOM in your CAD system and the M-BOM in your ERP/MRP system; and that’s where the Part-Book fits.